In carpentry, accuracy and precision in the building process depend on the use of measuring instruments. Accurate and exact cuts are difficult to make without measuring tools, which results in a less polished and professional looking end product. When you use measuring tools to make sure that your cuts and measurements are precise, you reduce the likelihood that any accidents will occur during building.

In a nutshell, those who want to make a polished and professional-looking carpentry job need a set of measuring tools. You can prevent errors and guarantee a quality end result by taking your time and using measuring instruments.

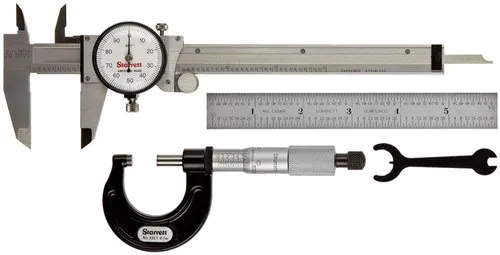

The various gauging devices found in the carpenter’s toolbox.

Carpenters rely on a broad variety of measuring devices to ensure the precision and accuracy of their work. These devices come in all shapes and sizes. A tape measure is the sort of measuring device that is used the most frequently. A woodworker might use a ruler to measure straight lines or a level to check for unevenness when working on a project. You can check out and buy measuring tools and levels in online shops.

The value of precision and exactness in woodworking.

Accuracy and precision are essential in many aspects of the carpentry profession. This is because many woodworking jobs involve building structures or products that must adhere to strict regulations for reasons of safety and functionality, such as homes or pieces of furniture.

One of the best methods to ensure precision and accuracy in carpentry is to make use of measuring tools. This is because accurate cutting and assembly of wood products requires exact measurements, which can only be obtained with a good set of measuring tools.

The correct way to use gauging devices.

Using measuring tools properly is of the utmost importance when working in carpentry or any other field that necessitates exact measurements. Although taking measurements may appear to be a straightforward job, if done incorrectly it can cause significant issues later on.

When gauging something, it’s important to remember a few guidelines. First, make sure you’re using the right tool for the task. Use the appropriate tool for the task at hand; for example, measuring length requires a different instrument than measuring width or depth. Second, make sure you’re using the right units of measurement. Although it may seem obvious, people frequently confuse measures when measuring, leading to incorrect results. Last but not least, before moving on to the next stage of your endeavor, always double check your measurements. Spending an additional few seconds checking your work can prevent hours of frustration later on.

The ability to accurately use measuring instruments is crucial for any carpentry job, so devote some time to mastering this skill. If you stick to the aforementioned guidelines, you can rest assured that your readings will always be precise.